Dynamic Range of Contactless Measurements

Contactless Measurement

Contactless current sensors like Tell-i DS10.2x series measure electric current without touching its current carrying trace. This feature allows seamless integration of the sensor into most complex power electronics circuits; specifically those using wide bandgap power semiconductor devices such as silicon carbide (SiC) and gallium nitride (GaN). On the other hand, pushing more and more high frequency currents into power PCBs requires a shift in layout design. Multi-layer power routing uses the board area more efficiently and reduces the interface’s parasitic impedance. Contactless and non-invasive current sensing addresses the need for emerging high frequency high power power electronics.

Contactless Non-invasive Sensing

Dynamic Range of Current Measurements

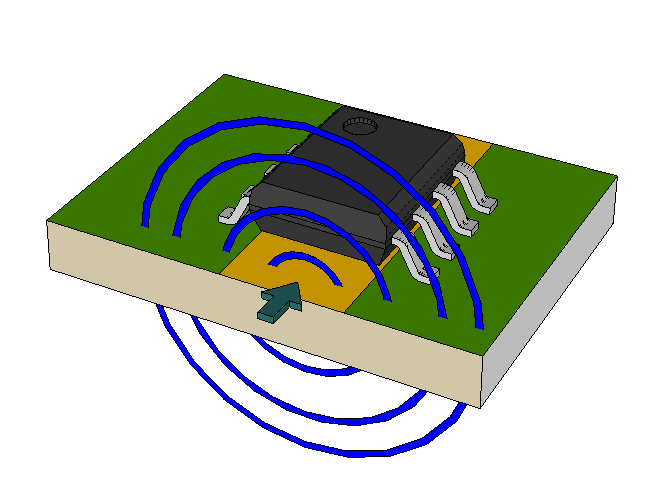

Tell-i contactless current sensors measure a dynamic range of currents. Tell-i current sensors use point-field detectors to measure the magnetic field generated from the current flowing in printed circuit board (PCB) traces. The magnetic field strength decreases with distance from the PCB trace. Unlike today’s invasive current sensors with a fixed measurement range, Tell-i sensors can be placed at different distance from the trace. For instance, DS10.2x series are 10A bidirectional ultrafast MHz sensors when they are mounted on top of a single PCB trace routed on the top layer of the PCB. The same sensor can be used for 30A current if the trace routed 0.125” from the sensor, figure below. This distance is equivalent to standard 4-layer PCB with 1 oz copper. The current can be distributed in multi layers of a power PCB to increase the efficiency (volume, conversion, and costs) of the board.